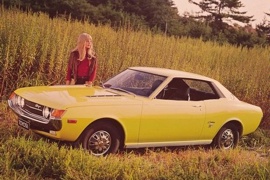

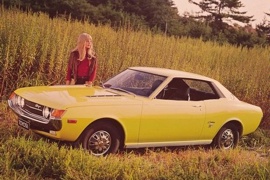

The original Celica dated back to the 1970 Tokyo Motor Show, where it shared media attention with the Carina. At launch there were two versions available, the LT (entry level) and ST (upmarket), both aimed at being more affordable versions of Toyota's sportscar, the

2000GT.

The lower-end LT was equipped with a 2T carbureted four-cylinder engine displacing 1,588 cc, while the ST came with a twin Solex-carburetor 2T-B derivative of the 1,968cc Corona 2000 engine. The latter engine used a cast iron block, alloy head, and a chain driven single overhead camshaft.

With a compression ratio of 8.5:1, the 2 litre version was good for 95 bhp @ 5000 rpm. There was also a GT version, with a more highly developed version of the 1,588cc engine, which developed 118 bhp @ 5,800 rpm thanks largely to the twin Mikini-Solex Carburettors.

At its introduction the Celica was only available as a pillarless hardtop. The SV-1 liftback was shown as a concept car at the 1971 Tokyo Motor Show. With slight modifications, this was introduced in Japan in April 1973 as the 2000 cc RA25 and 1600 cc TA27 liftbacks. It was then exported to Europe in RHD form as the 1600 cc liftback.

The first iteration of the Celica featured a slant nose (trapezoid-like shape front corner light), and was available as a Coupe model only, designated the TA22, RA20, and RA21. These models were released from 1970 to 1975 and came equipped with the 2T, 2T-G 1.6 litre, or 18R 2.0 litre engine, although those bound for the US came with the 18R engine.

A minor revision would see the 95" wheelbase extended by three inches to 98", and minor changes to the front giving the car a flatter nose and square front corner light. Although the revised model made its debut in Japan in 1974, export models were only released for the 1976 model year.

From 1972 to 1974 US bound Celica's were fitted with the 2.0 litre 18R-C engine. It increased in size again for the 1975-1977 models, now being fitted as standard with the 2.2 litre 20R engine. The Celica GT and LT models were introduced in the U.S. for the 1974 model year. The top-line GT included a 5-speed manual transmission, rocker panel GT stripes, and styled steel wheels with chrome trim rings.

Other changes for 1974 included minor changes in the Celica's trim and badges, and an automatic transmission became an option on North American ST and LT models starting in the 1973 model year. For 1975, the '74 body was used, but body-color plastic fascia and sturdier chrome and black rubber bumpers, replaced the chrome bumpers used in the earlier cars (in accordance with US Federal bumper laws).

The First Facelift

In October 1975 the entire Celica lineup was given a facelift, with a revised front bumper and grille arrangement. The new model numbers were RA23 worldwide (RA24 US) for the coupe, and RA28 worldwide (RA29 US) for the liftback. The American Liftback was a GT (RA29) with a 2.2 litre 20R engine. All the Liftback models, which were commonly referred to as the 'Mustang' shape, had flat noses. Although there was no "B" pillar in the Liftback, the rear windows did not roll down (as they did in the hardtop coupe).

Although they looked the same, there were a few minor visible differences. The facelifted coupe was coded RA23 with an 18R engine, or RA24 with a 20R engine. Also available was the TA23, which was similar to the RA23, but with the T-Series engine. The RA23 and RA28 had a more distinctive bulge in the bonnet, or hood, which was lacking in the TA22 or RA20 Coupe and in the TA27 and RA25 Liftback Celica. The TA22 Celica also had removable vents mounted in the bonnet, which the RA23 and RA28 lacked. The RA series also had an elongated nose to accommodate the larger engine. The door vents, fuel filler cap, and interior were also different between the TA and RA series.

Although the Liftback was virtually the same size as the then current ST, being 0.8 inches shorter overall, the same width (63.8 inches) and 0.6 inches lower, and with the same 98.2 inch wheelbase, the car did appear to be noticeably larger and better balanced. And of course the liftback added to the cars versatility, however there was a drawback - the extra metalwork and glass area added considerably to the Celica Liftback's weight, it now tipping the scales some 210 lb. heavier than the ST. A five-speed gearbox was standard, with a true over-drive top gear pulling 20.1 miles per hour per 1000 rpm.

The suspension setup was conventional, using MacPherson struts at the front, and a well-located live axle at the rear, with trailing links. The Liftback also differed from the ST in running on 14 in. diameter wheels shod with Dunlop SP sport tyres, with 165 section. With its greater weight and higher overall gearing, the liftback was slightly slower than the ST, however on the credit side many found the liftback exceedingly smooth and easy to drive, the power curve being sufficiently smooth to allow the engine to be taken right up to the rev counter red-line at 6,500 rpm.

Standing starts produced just the right degree of wheelspin to keep the engine on cam; there was no hint of time wasting axle tramp. As was usual of Japanese cars of the time, the gearbox was superb, with the lever biased just correctly into the centre, 3rd/4th gear plane. Fifth was up and to the right, reverse being guarded by a further slight movement to the right down from the neutral plane, and down. In the lower three gears, maximum speeds at 6,200 rpm were 33.53 and 77 mph, while in fourth, pulling 17.4 mph/1,000 rpm, it was possible to break the 100 mph mark, at just over 5,700 rpm. The liftback reached 40 mph in 6.1 seconds, 50 in 8.7 and 60 in 12.7, with the quarter mile mark being passed in 18.8 seconds. The 0-60 mph time compared to 11.4 seconds for the Ford Capri 2000S and 11.2 sec for the Vauxhall Cavalier GL coupe.

As was becoming common in the early 1970's, the Celica was yet another Japanese car which ran on the lowest grade (and least expensive) two-star grade fuel. This fact, allied to the overall figure of 27.8 mpg, made the Celica a remarkably economical car to run. At a constant 70 mph, consumption was still the right side of 30 mpg (30.5 mpg to be exact), but reviewers of the day noted a noticeable faIl off in economy at higher speeds, and flat-out driving around the 100 mph mark put consumption down to around the 16-17 mark.

The main instruments included a speedometer (left) with press-to-zero trip reset, and rev counter (right) with direction indicator and main beam warning lights between. The centre panel housed the clock, oil pressure, ammeter, coolant temperature and fuel gauges. Vertical rows of warning lamps operated only on brake circuits on UK cars. Four slides for heater control, with heated rear window switch to right as standard and FM / AM radio. The bonnet release was beneath the fuse panel on right. The horn buttons were located on the steering wheel spokes.

When hustled into corners the Celica exhibited much less roll than contemporary family sedans.

There was no major increase in the understeer as speed rose and, ultimately, the car would tend to run a little wide. Really violent cornering would lift the inside rear wheel, but even under these conditions, the car remained remarkably stable.

At over 95 mph, the front of the car could start to feel a little light, a small spoiler would have improved things much better than the vestigial lip over the tailgate. Noise levels were low although, at over 5,000 rpm, the engine was plainly working pretty hard, with a good deal of mechanical thrash. Generally, however, overall levels were well within acceptable limits.

In braking the Japanese made great advances in the early 1970's, thanks largely to their participation in world-wide competition events. The disc-front, drum-rear set-up, with a vacuum servo, gave the Celica a very sure-footed feel. was is ideal, with 20lb pedal pressure needed for in-town check braking (around the 0.3g mark), while 70lb would give a near-perfect 1.Og stop, with just the slightest squeal from the locking rear tyres and not much nose dip.

After reading countless reviews, it is evident the Celica's brakes stood up well to the fade test, with pedal pressure needed for the 0.5g stop rising on average from 30-25lb for the first stop to 40-50lb.

There lift back facility turned the traditional limited-space sports coupe into a sensible load carrier. The tailgate on the Celica had a key-only lock, and was supported on a pair of gas-filled struts. With the back seat in position, there was 10.3 cu. ft. of luggage space against the 7.7 cu. ft. in the standard Celica, and this could be increased to a really sensible 25 cu. ft. with the rear seat folded flat, although the rear suspension mounting covers did take up a fair amount of room.

The problem of covering up luggage, always a problem in liftback coupes, was solved in an elegant manner. A simple "roller blind" was attached to the rear of the back seat and this could be simply pulled out and attached by press studs, either to the edge of the tailgate or to the sill. In the first position, the "blind" simply unrolled itself to cover the luggage as the tailgate was closed. A further refinement was the provision of a V-shaped webbing strap to stop a single suitcase from sliding about on the carpeted floor. The spare wheel and the useful tool kit were stowed in lidded lockers beneath the boot floor

While the front seats were comfortable, they did lack sufficient wrap-around to provide sufficient support in cornering. Also, the padding tended to feel a bit thin after a long trip. These criticisms apart, the seats were not over-bulky, allowing rear seat occupants, whose leg and head room was restricted, to make the most of the available room. The rear seats, with deep "buckets" either side of the thinly-padded transmission tunnel, were adequate for children, but a bit cramped for adults. Owners soon discovered that the wells made a useful place to carry small, fragile items when the rear seat was folded down.

The driver had a very full span ot instruments, all very clearly lettered. In front of the driver was the rather wildly optimistic speedometer (reading 77 at a true 70 mph), with a push-button trip recorder (three per cent over-reading), and the rev counter, yellow-lined from 5,400 rpm, red-lined from 6,500 rpm: In the centre of the facia, and with their anti-reflection cowls angled towards the driver, were the combined fuel and coolant temperature, oil pressure and ammeter dials, with the clock separate. An ammeter was fitted, which of course gives much more information than a battery voltmeter. A vertical row of warning lamps on UK specification cars contained just the handbrake "on" and hydraulic fluid level lamp. For other markets the lamps were linked to an electro-sensor system which monitored items like engine oil, battery and the windscreen washer reservoir.

The Celica was successful in the showrooms of the world. It was not particularly powerful, and demonstrated regulation handling and performance. No, it was not a drivers car, but it looked the goods and did everything you asked of it with typical Japanese efficiency. Sure, you could spend the same amount of money on a British sports car, and for some that would make a better choice. But for those that wanted the assurance of their car starting each and every morning with monotonous reliability, the Celica was a hard car to pass up.